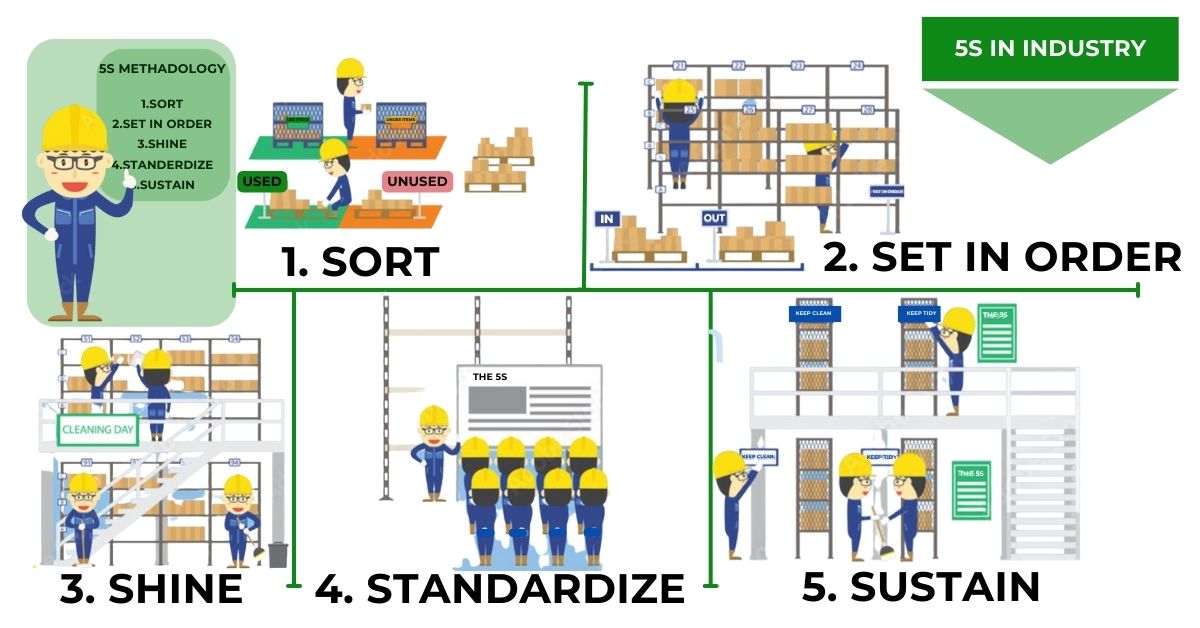

What is 5s methodology?

- Sort (in Japanese it is known as Seiri)

- Set (in Japanese it is known as Seiton).

- Shine (in Japanese it is known as Seiso).

- Standardization (in Japanese it is known as Seiketsu).

- Sustain (in Japanese it is known as Shitsuke).

1. Sort

Classify all items in two sections and write down all items in a list. Then look at the items that are not in good condition for use or not repairable and put them aside. Then the items used one time in a year or used for special occasions were put in and out of the Department of Health and me

2. Set

Keep needed items in the correct place to allow for easy and immediate retrieval.

3. Shine

Keep the workplace and items neat and clean.

4. Standardize

The method by which “sort” “set” and “shine” are made habitual.

5. Sustain

Maintain established procedures.

Sort the Items

First you look at the monthly use items or you use it generally 5 to 6 times in a year and put it on another side.

If you look at items used every week or in-house, you use them on the weekend and put them on the other side.

Then, you look at the items on a daily basis and put them in front of you.

Rack 5S Rule

Design your rack/ cabinet

Straighten/set

Set in a specific order the items you need. Set all items after categorizing them.

For example, the industry sets parts of machines with all parts using the same machine. They should be placed in the same part or cabinet, like the pump/ gearbox/ decelerator/ chains. And use at the specific machine the parts of this type should be placed by category of machine type.

If a part is used in all types of machines, place all part types in the same place. Like pneumatic fittings/ but and bolt/ bearing/ belts. The part should be placed in view so any person can understand the part type from a distance. Labeling of all parts is placed and you can use the label in the body of the part for that purpose. Label instructions/pictures. The locator should be designed for this purpose so anyone can find the part. The compatibility part placed with the locator is very important for better results in 5s.

Shine.

Cleaning of objects, parts, and the working place is very necessary. Dust on parts is not good-looking. Daily cleaning of all the tools, machine parts, and working place is a good habit and looks good.

Shine is the main pillar of the 5s. So we should clean all parts and the working place daily and make a shine list to perform shine activity with record and daily. To shine, we can use cast acrylic transparent sheets to make covers of objects or part boxes. The cleaning of sheets is easier than the object. To clean or shine we use compressed air, we should not do this. It is not safe and secure, it is also costly and also creates some faults in parts or objects.

Standardize

This method by which ” sort” ” straighten” and ” shine” should do daily in our homes and work and our personal lives. If we make a record and checklist physically daily we can standardize this action. For example, we bathe, we brush our teeth and we polish our shoes as generally saying we do all this work daily but sometimes we can’t polish the shoes due to lack of time and we are in a hurry so we have no record. If we have a record and checklist this thing tells us how many days we are not doing this work. Checklists and records give us responsible reminders about the mentioned work. So this thing makes our life a standard Life.

Standardization is more important in the industry than life because, in the industry number of departments and the number of objects and machines, we easily manage all machines by standardization. Checklists and good record keeping are good habits in personal and working life.

Sustain.

Maintain all the procedures to establish this procedure correctly and honestly this is called sustain.

Sustainability is the key to success in business and life. A good habit in my personal life and a big achievement in industrial life.

Causes of 5s

- Good looking and good feel.

- Better and easy cleanness.

- Space management.

- Parts/ objects management

- Knowledge of every item.

- Easy access to each item.

- Know the placement of every item and object.

- Object condition betterment

5s in Mechanical Workshop

5s in Electrical Workshop

5s in the Hardware Store

5s in Personal Life

5s in Office

5s General Store

5s in the House

5s Document