What is Kaizen?

Kaizen is a Japanese term meaning “change for the better” or “continuous improvement”. It is a concept of small improvements that continuously improve all functions (E.g., performance, cost, quality, etc.).

As an industrial worker:

Kaizen is a methodology for solving problems at your base for your betterment in the future. Like inventing a new machine or making better amendments to a machine for better performance is also a kaizen. Make any changes in the system that will be beneficial for the production improvement in any term.

Lean and Kaizen

Lean is a complete setup of strategies that make a product a quality product. But Kaizen is a strategy for continuous improvement in this setup like cast control, safety, quality, etc. You can also say that the kaizen is a pillar of the lean manufacturing system.

Types of Kaizen

1 Qualitative Kaizen:

A Kaizen that has a direct Impact on Safety, Quality, Delivery, Fatigue, and Morale is considered a Qualitative Kaizen.

2 Monitoring Kaizen:

A Kaizen that has a direct impact on Cost Saving/Productivity is considered a Monitory Kaizen.

3 Rollout Kaizen:

Kaizens that can be implemented within /other Companies or Plants are considered Rollout Kaizens.

Purpose

To develop & strengthen Kaizen culture by engaging shop floor employees to successfully generate and implement Continuous Improvement Activities to enhance Productivity, Efficiency, and Quality. Kaizen can cause process improvement.

To improve employee motivation and engagement through a reward and benefits system to create a culture of continuous improvement, problem-solving, and teamwork to achieve sustainable results.

Scope of Kaizen in the Industries

Kaizen encapsulates all Manufacturing and Non-manufacturing areas under the scope of the Plant Head or The Responsible Personality. This strategy covers Idea Generation, Kaizen Implementation, and Reward Mechanisms within the production units.

The scope of this procedure encapsulates all types of industries and all the departments in the industry. Functions under the scope of the department are mentioned below.

- Industry Management Department

- Product Operations Department

- Energy Excellence | Utility Department

- Engineering Excellence Department

- Quality Assurance Department

- EHS and Safety Departments

- Process Excellence Department

- Warehousing & Logistics

This information will provide you with the process to implement the kaizen strategies and reward selection at best Kaizen at the Organizational level.

Definitions / Abbreviations

- TM: TM stands for Team Member

- TL: TL stands for Team Leader

- GM: GM stands for Group Member

- GL: GL stands for Group Leader

- SOP: Standard Operating System

- CEO: Chief Executive Officer

Examples of Kaizen

Here is an example of kaizen in the Industry after this you can easily understand about Kaizen and its benefits.

Kaizen in Toyota

The kaizen system was first implemented in the Toyota Motors company. Toyota emphasizes making small, incremental improvements over time to achieve maximum quality and efficiency.

Implementing Kaizen in the Industries

This Standard Operating Procedure (SOP) will provide a standardized framework to reward Kaizen, which has contributed to enhancing Quality, Productivity, and Delivery and reducing Manpower and Cost of a particular process/operation.

Kaizen is a strategy for developing continuous improvements in the industry and life. Implementing this strategy has a few steps to follow. These are Kaizen Strategy Methods.

1. Introducing Kaizen to Others

Arrange a meeting and hold a seminar to meet with all workers, including officers, and introduce them to Kaizen, its purposes, and benefits. Generate Kaizen findings and ideas according to departments. Create a Kaizen in every department and use this Kaizen as an example.

2. Introduce Kaizen Reward

Motivate all workers for Kaizen and Idea generation strategy. Introduce the Company Management System for Kaizen.

3. Necessary Documents

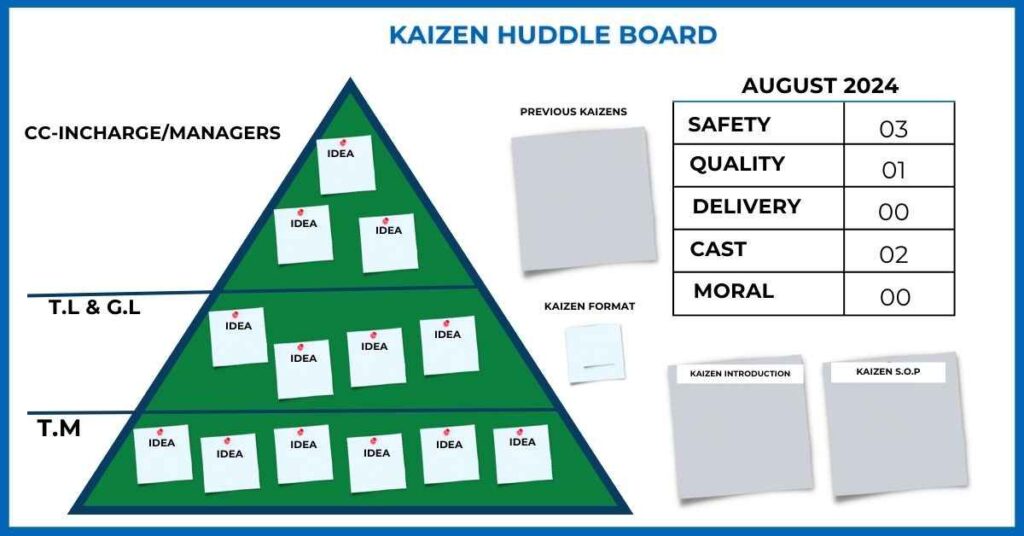

Introduce to others the Kaizen Huddle Board and its Elements and some important documents. Like

- SOP for Kaizen according to company policy.

- Kaizen details and impact points.

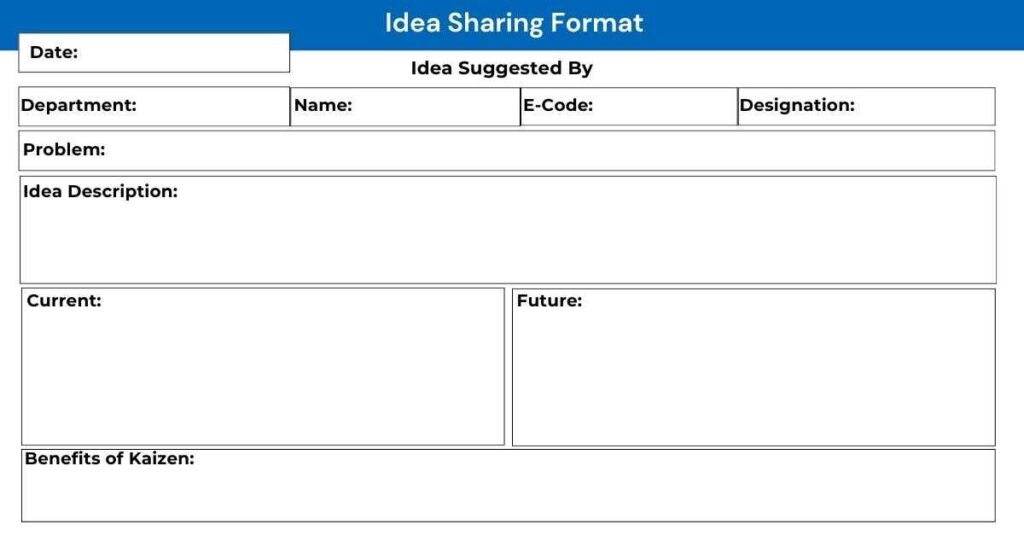

- Idea sharing format and use.

- Kaizen Effectiveness Analysis.

Responsibility

The Lean Representative & Department HOD will administer and execute the SOP in its letter and spirit.

Responsibility of the Corporate Learning Team

- Establish, Implement, and Validate Kaizen Generation & Implementation Policy.

- Organize and document Kaizen events in the company after completing the Kaizen process.

- Conduct Kaizen Training and Awareness Sessions in the company.

- Select the best kaizen for rollout and support the implementation team.

- Performed monthly audits through Gamba Walk to check the sustainability of the kaizen.

- Establish and Update the Dashboard to Monitor & Track Implemented Kaizen.

Responsibility of the Lean team:

- Follow up on the Kaizen Implementation Process in the respective department.

- Evaluation of ideas and Kaizen.

- Support in Kaizen Implementation and Documentation.

- Support the Operations Team in the Kaizen Event.

- Roll out the best practices in the concerned department.

- Ensure the sustainability of the Kaizens.

- Department-level Kaizen Reward ceremony every quarter.

Kaizen Implementation Procedure

Here are two processes for completing a Kaizen strategy

- Kaizen before the Final Evaluation.

- Kaizen after the Final Evaluation.

1 Idea Generation Process

2. Idea Collection and Evaluation Process

3. Kaizen Implementation

4. Kaizen Rollout

5. Kaizen Rewards

6. Kaizen Sustainability

Idea Generation Process

Here are some kaizen methods or kaizen ideas collection/generation methods.

- Through Kaizen Huddle Board

- Through SVM (Value Chain Management)

- Through Gamba walk

1 Through Kaizen Huddle Board (Bottom-up Approach)

(a). The Company Lean Representative will be responsible for maintaining the Kaizen Boards and updating the progress in the Kaizen strategy. The Lean Team will provide a Standard Idea Sharing Format along with the Kaizen Huddle Board.

(b). Operations Team (TL/GL/CC Incharge) must conduct a Stand-up Meeting near the Kaizen Board. The Lean Team should inform the Operation Team about the Kaizen Process.

(c). The meeting schedule is as follows

- TLs of each department will collect suggestions from each TM in each shift and paste suggestions on the Kaizen Board.

- TM can also paste suggestions directly on the Kaizen Board at any time.

| Meeting | Timing |

|---|---|

| The Lean Team Head and Lean Implementation Team will start working on these Kaizens. | Every Monday (10 Minutes) |

| TL, GL, and Lean Head meeting on Ideas with details | Every Monday (30 Minutes) |

| The Lean Team Head and Lean Implementation Team will start working on these Kaizens. | Every Monday (01 Hour) |

| Lean Team Head and Lean Implementation Team will start working on these Kaizens. |

(d). Ideas/Suggestions must be presented on the Kaizen Board by the TL/GL/CC Incharge in every Stand-up Meeting.

(e). Ideas will be filtered on the Kaizen Board through a bottom-up approach as mentioned in the Kaizen Board below.

2 Through VSM

Kaizen Identification through detailed VSM (Value Chain Management) of the facility.

- Through Kaizen sessions and Events.

- The Lean Team Head and the Company Heads (with the support of the Corporate Lean Team) will be responsible for organizing a Kaizen Event in their respective departments.

- All the Identified Ideas/Kaizens will be segregated and prioritized. Kaizens requiring minimum effort/resources and having a high impact will be implemented in a Kaizen Event. An Implementation Plan will be developed for the rest of the Kaizens.

3 Through Gemba Walk

Kaizens will be generated by performing a Gemba walk according to the criteria below to identify opportunities and Gaps. The Company’s Lean Representative will document them.

| Gamba walk Leader | Weekly basis |

|---|---|

| Lean Team Head and Lean Implementation Team Head | Daily as Routine |

| with the CEO of the Company and with Managers and Lean Heads | Weekly base |

| Frequency | Monthly basis |

Idea and Kaizen Sharing Process

- The concerned Operations Plant or Unit Head for Lean Implementation will share the ideas using the Standard Idea-sharing format. The template for the Registration Format idea-sharing should be designed first and available on the Kaizen Huddle Board. The Idea-Sharing format should be designed with complete and necessary details.

- Concerned Plant or Unit Head Operations will share the Kaizen in Standard Kaizen format with The CEO of the company. with the implementation process and validation of monetary savings.

- The rewards will be given to the implementation team that is directly involved in executing Kaizen in the Pilot area (Department/Line/Machine/Cell, etc.).

Ideas Collection and Evaluation Process

- The Company Lean Representative will collect the Ideas from the Kaizen Board after meeting with GL and the CC-Incharge.

- Department Head or Lean Head the Process Excellence Team will conduct the 1s Evaluation after receiving every Kaizen to check whether this Kaizen is eligible for reward.

- The Company’s Lean Representative will refine, evaluate, and prioritize the ideas for Execution.

- The Lean Representative and the Department in charge of Lean Implementation will accept or reject the idea.

- The unit head or manager of the Lean Process will conduct the Kaizen Forum Incharge Lean Implementation before the Kaizen Reward Ceremony.

- The concerned Company Budget Representative will be responsible for validating the financial impact of all Rewards.

Kaizen before the Final Evaluation.

The evaluation committee will validate the Kaizen through Gemba and data according to the criteria for its reward qualification.

The unit Head or Manager Lean Process Excellence Team will strictly control to avoid the repetition of Kaizen for reward nomination using the Centralized Kaizen SOP.

The Evaluation Committee will conduct a final Evaluation of the Kaizen Reward Ceremony to ensure Kaizen’s Sustainability in the pilot area.

The Evaluation Committee Members

- The CEO of the company

- Concerned Manager or Plant Incharge

- Concerned Department Head

- Lean Head of Process Excellence

- Concerned Budgeting and Finance Head

These members will assess and endorse the Kaizen for reward and benefits.

Kaizen implementation

- Plant Lean Representative with Unit charge will define Implementation Teams and the Deadline and will specify the support required from Engineering, JIDOKA, and Corporate Lean for Kaizen implementation.

2. The Kaizen Implementation Team will be responsible for successfully implementing the Kaizen and producing the expected results.

3. The Plant Lean Representative, Operations Representative, and Corporate Lean Representative will perform monthly GEMBA to validate the Kaizens.

4. Non-manufacturing areas (e.g. Quality, Engineering, Technical, Support Services, etc.) will submit their Kaizens to the Plant Lean Representative. Plant Lean Representatives will evaluate & Share the Kaizens with the Corporate Lean team.

5. After the successful implementation of Kaizen, the Plant Lean Representative will document the Kaizen in Standard Kaizen format and will share the Kaizens with the Corporate Lean Representative by the last date of each month.

6. The Corporate Lean Representative will be responsible for updating the progress of each Kaizen on the Kaizen Dashboard.

| Activity | Event |

|---|---|

| Kaizen Ideas Collection/Receiving and Initial Evaluation | Every Monday |

| Kaizen Implementation Process | ASAP |

| Kaizen to be Considered for reward | After Sustainability |

| Final Evaluation | After Calculation Process |

| Reward Ceremony | Ensure Sustainability |

Kaizen Rollout (Yokoten)

Plant Lean Representatives will be responsible for the Kaizen Rollout within the Plant.

If Kaizen is feasible for Rollout across the divisions, the Corporate Lean Representative will share the Standard Kaizen format with all Plant Lean Representatives and Roll out the Kaizen as per the “SOP for Kaizen Rollout and Standardization.”

The Corporate Lean Representative will maintain and update the Kaizen Rollout Dashboard to monitor the Rollout Status.

Kaizen Rewards

Reward Benefits

- Idea Generator: Motivate the Idea Generator to generate more ideas like this and get financial support.

- The Company: All the workers will motivated for finding Kaizens to get rewards.

The Lean Team Head and Representative will select the best Kaizens every Month for Rewards based on the Kaizen Evaluation Sheet.

The Lean Team Representative along with the Plant HR Representative will also select the best few suggestions for reward as well. These suggestions can come from any area through any source (e.g. Kaizen Triangle Board, Suggestion Box, Idea Sharing Process), etc.

The Lean Team Head will also be responsible for finalizing the budget reward against finalized Kaizens.

The Kaizen Implementation Team Head will be responsible for getting the budget approved by the Company CEO.

The Lean Team will be responsible for organizing the Kaizen Reward Ceremony. The Company HR Representative will also join the Kaizen Reward Ceremony arrangements.

Eligibility Criteria for Reward Scheme

Sign-off process completion on Standard Kaizen Format.

Kaizen should be able to generate defined monitory savings for the Organization/Company.

Improvements should be implemented in the Pilot Area.

The standard/SOP, related to the Kaizen, should be revised and visualized.

The improvement results should be sustained for a minimum time frame in the pilot area as per the company SOP.

Shop floor teams should be trained on the new standards in the pilot area.

Budget Calculation and Approval

The Finance Manager of the Company or Lean Team Head will calculate and decide the Reward % which will be decided between 10% to 20% range according to the Company SOP. Table 5.i & j (Financial Matrix for Reward & Reward % Distribution Matrix).

The reward amount will be calculated by considering the demonstrated savings generated through the implementation of Kaizen in the concerned cost center Pilot area during the specific time.

The Lean Team Head will present all the selected Kaizen for reward to all participants of the Kaizen Process before the Reward Ceremony will be presented to the CEO for final consent.

The CEO of the Company will recommend the required budget and reward category for approval to the Finance Manager or Lean Team Incharge who will be the approving authority as per SOP.

Lean Team Incharge along with the concerned Company HR Representative will be responsible for incorporating the Kaizen sustainability.

Lean Team Head will recommend the type of reward as mentioned in

Financial Matrix for Reward

| Demonstrated savings through Kaizen | % from total savings | Reward Amount | Idea Generator Amount | Implementation Team Amount |

| More Then $10,000/- | 10%-20% | $1000/- | 20% of rewarded amount | More Than $10,000/- |

Reward Distribution Mechanism

In most Companies 20% of the allocated budget for rewards will be evenly distributed among the idea generators.

80% of the allocated budget will be distributed among all the implementation teams according to the defined criteria.

Idea generators can also be part of the Implementation team.

If the idea does not belong to individuals, then the entire allocated reward budget will be evenly distributed among the implementation team.

If the idea is given by Managers and above, they may be considered for monetary reward across the concerned department. Their contributions will be acknowledged through certificates & Dinner Coupons.

The Lean Implementation Team may be rewarded additionally by the Company Authorities if the Kaizen has been rolled out.

The Lean Implementation Team will be rewarded a specific percentage from specific time Savings through Kaizen. Which has completed 100% rollout in their respective department and the company Head will vet the Kaizen rollout in each Plant.

Reward Distribution Event

Kaizen Reward Distribution Event or Kaizen Event is the same thing and only difference in words.

Arrange an event to give the reward to the Idea Generator and Implementation Team as per company policy for the Kaizen Management System.

The Lean Team Excellence will initiate the Kaizen Celebration Event Reward Ceremony and ensure the necessary communications to all concerned teams.

The VP-level position will be invited as a Chief Guest for the ceremony.

All Company Heads, Concerned Department Heads of Lean Implementation/Representatives, and Kaizen Teams will be invited to the event.

Reward % Distribution Matrix

| Kaizen Type | Defination | Reward Percentage |

|---|---|---|

| Operational | Only for pilot area implementation | 10% |

| Tactical | Can be rollout throughout whole company | 15% |

| Strategical | Can be rollout throughout more than one plant | 20% |

Reward Category

| Category | Designation | Reward |

|---|---|---|

| Workers | Helpers, Operators, Mechanics, and similar grades | Cash, Gifts, and Certificates |

| Supervisor | Forman, Junior Officers, and similar grades | Cash, Gifts, and Cirtificates |

| Executives | CEO, Managers, and Senior Officers | Dinner and Certificates |

Sustaining Mechanism for Rewarded Kaizen

The Head Lean Team and Lean Implementation Team will do a time-to-time audit on the Process where Rewarded Kaizen has been implemented and share the report Lean Head and Company Head.

Lean Team Head and Lean Implementation Team will highlight the implementation gaps to Plant Operations Senior Leadership and ensure its implementation with the concerned Operations Team.

The Lean Head & Lean Implementation Team Head will do the Gemba to check the parameters on the sustainability of rewarded Kaizen in the implemented areas frequently.

The HOD of the Concerned Department and the Head of Lean will share the sustainability report.